KQ Series Big Ceiling Fans Giant HVLS Fans for Large Space

SUPER LARGE INDUSTRIAL ENGRY-EFFICIENT FAN

KEY FEATURES

● Outstanding coverage without draft,fully encompassing air circulation.

● Super energy saving ,cut the HVAC and air condition cost up to 30% or replace them.

● Efficient cooling effect makes people feel 5-8 temperature cooling ,improve staff productivity.

● During the winter ,HVLS FAN mix the hot air produced by the heaters with the cold air ,reducing 30% heating costs.

● Consitent ventilation keep wet and moist area dryer and prevent hot air condensation .

● Warranty ( whole fan unit 3 years , fan blades and hub for lifetime ).

| Model | Fans Diameter

(m)ft |

Motor Power

(KW/HP) |

Speed

(Rpm) |

Air volume

(m³/min) |

Full load current

(A)380V |

Weight

(Kg) |

| OM-KQ-7E | 7.3m/24ft | 1.5 | 20-53 | 14,500 | 2.9 | 126 |

| OM-KQ-6E | 6.1m/20ft | 1.5 | 20-58 | 13,200 | 2.4 | 118 |

| OM-KQ-5E | 5.5m/18ft | 1.5 | 20-64 | 12,600 | 2.2 | 114 |

| OM-KQ-4E | 4.9m/16ft | 1.5 | 20-70 | 11,000 | 1.9 | 109 |

| OM-KQ-3E | 3.7m/12ft | 1.5 | 20-75 | 7,200 | 1.8 | 102 |

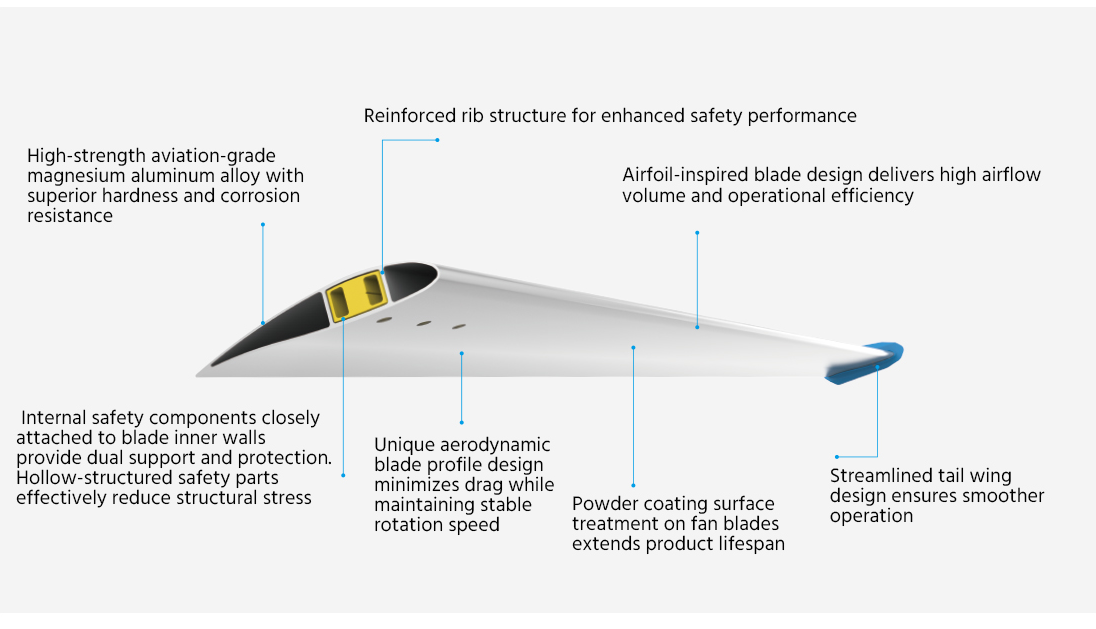

| Fan Blades - The Ultimate Implementer of All Functions |

1. Aerodynamic Design: The blades feature an aerodynamic profile engineered through computational fluid dynamics (CFD) optimization, delivering 23% greater airflow volume, 18% higher energy efficiency, and 35% wider coverage compared to conventional fan blades.

2. Premium Material Construction: Forged from aerospace-grade 6063-T6 magnesium- aluminum alloy through precision die-casting, these blades achieve Vickers hardness of 85 HV while maintaining exceptional corrosion resistance (withstands 500-hour salt spray testing per ASTM B117).

3. Advanced Surface Engineering: A multi-stage powder coating process creates a 50-70μm oxide ceramic matrix composite (CMC) layer, demonstrating >9H pencil hardness and UV resistance exceeding 3,000 hours per ASTM G154.

4. Reinforced Structural Architecture: The dual-phase reinforcement system combines radial stiffening ribs (3mm thickness) with iso-grid safety webbing, achieving 1520 MPa yield strength while reducing turbulent energy loss by 42% through optimized mass distribution.

Case Presentation

Email:chenzhenxiang@optfan.com

Email:chenzhenxiang@optfan.com